Expert Welding and Fabrication Techniques for Square Steel Tubing in Modern Construction

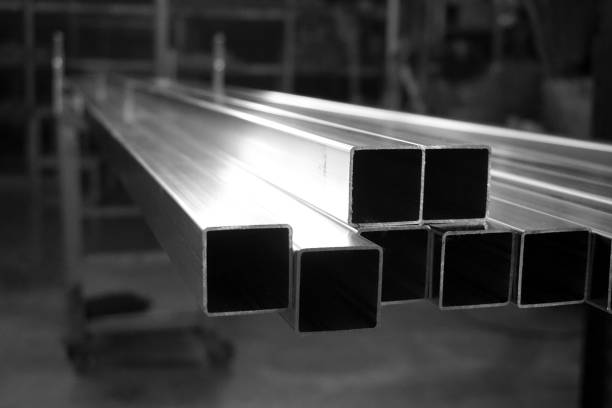

Square metal tubing is a extensively used issue in nowadays’s construction panorama. Known for its power, durability, and uniform look, it’s a favored cloth for numerous load-bearing and architectural programs. Whether utilized in business framing, infrastructure guide, or custom fabrication, this form of metallic tubing offers a stability among functionality and design. For builders, engineers, and fabricators, getting to know the welding and fabrication of rectangular steel tubing is vital for efficient task delivery.

Construction tasks often require more than one structural metallic products, and square steel tubing ranks most of the most flexible. It may be cut, fashioned, and welded to form frameworks, braces, columns, and trusses. The uniform geometry and indoors void of square steel tubing make it perfect for structural energy even as last exceptionally lightweight. From railings to supports, understanding the way to well weld and fabricate rectangular tubing can considerably impact the very last excellent and sturdiness of your structure.

Preparing Square Steel Tubing for Welding

Surface Cleaning and Material Inspection

Proper preparation starts with making sure the tubing floor is easy and free of contaminants. Before any welds are made, oil, rust, mill scale, and paint must be removed to create a solid bonding vicinity. Even minimum floor residue can lead to weak welds or inconsistencies. Using a wire brush, grinder, or chemical purifier ensures the tubing is ready for satisfactory weld penetration.

Inspection is equally essential before starting any cutting or welding. Look for dents, bends, or choppy wall thicknesses that could affect how properly the tubing fits or how pressure is shipped after fabrication. Early detection of defects can save you structural screw ups and ensure the lengthy-term integrity of the set up.

Planning the Joint and Layout

Welding square metal tubing regularly entails planning miter joints, butt joints, or T-connections. The uniformity of the tubing lets in for particular angular cuts, making it simpler to gather complex frames and architectural components. Proper dimension and format are essential to avoid warping in the course of welding or misalignment in the final product.

The joint configuration have to bear in mind load distribution, visual look, and ease of access for the welding manner. Clamps, jigs, or custom furniture may be used to maintain the tubing in area all through the welding process, making sure consistency throughout the workpiece.

Best Welding Techniques for Square Steel Tubing

MIG Welding for Efficiency and Clean Finish

MIG (Metal Inert Gas) welding is a not unusual method used for rectangular tubing in creation initiatives. It lets in for quick welds with minimum cleanup and is right for lengthy directly runs. The shielding fuel protects the weld from contamination, and the non-stop cord feed guarantees a regular arc. This approach is specifically powerful for medium-gauge tubing, supplying energy and an aesthetically clean finish.

MIG welding is consumer-friendly and can be finished in diverse positions, which includes vertical or overhead. This flexibility makes it suitable for on-site welding at some point of framework meeting or prefabricated panel creation.

TIG Welding for High Precision Applications

TIG (Tungsten Inert Gas) welding is favored while the highest fine or unique work is needed. It offers precision and control, making it ideal for thinner square metallic tubing or visible architectural factors. Although slower than MIG, TIG produces a purifier weld with better manipulate over warmth enter and puddle formation.

For initiatives concerning creative design or delicate structural element, TIG welding can provide exceptional results with out immoderate grinding or finishing. However, it demands extra skill and staying power, regularly making it more suitable for indoor or controlled environments.

Stick Welding for Heavy-Duty Structural Work

In environments wherein system portability and fabric thickness are essential, stick welding is a solid alternative. This approach makes use of flux-coated electrodes and does no longer require protecting gas, making it perfect for out of doors creation or subject repair jobs. While it produces extra spatter and slag than MIG or TIG, stick welding is particularly dependable for heavy wall rectangular tubing and rugged programs.

Stick welding is specially powerful for thicker structural steel merchandise that need sturdy, penetrative welds. It’s less dependent on environmental conditions and greater tolerant of youngster floor contamination, which is often a venture on process web sites.

Fabrication Tips for Accurate Assembly

Measuring and Cutting with Precision

Cutting square metallic tubing to length requires both accuracy and interest to blade kind. Using a cold noticed or band saw gives easy edges that assist with tight-becoming joints. Miter cuts should be made with an perspective manual to ensure consistency, specifically whilst assembling frames or containers.

To make sure that tubing suits efficiently, the measuring equipment used must be well calibrated. Even minor miscalculations can create choppy joints or strain factors, which compromise the structural performance of the finished piece.

Managing Heat Distortion During Welding

Square tubing may be prone to warmness distortion because of its hollow form. The flat facets extend whilst heated, leading to warping if now not nicely controlled. Techniques consisting of staggered welds, preheating thicker sections, or welding from the middle outward can help control this distortion.

Clamp aid all through welding is likewise vital. By securing the tubing firmly, you can lessen unwanted motion and make sure that your alignment stays intact. Allowing welds to chill step by step instead of hastily can also lessen pressure and help hold the tube’s form.

Grinding and Finishing for Clean Edges

After welding, grind the welds to smooth the floor, especially if the tubing will be visible or part of an architectural characteristic. A flap disc or grinding wheel can assist do away with extra cloth and put together the tubing for finishing or portray. For exterior installations, applying a protecting coating after fabrication is vital to save you corrosion and keep the metallic’s integrity over the years.

Grinding additionally performs a role in protection, ensuring that no sharp edges or burrs are left that could purpose damage all through set up or use. In high-visibility programs, consistent finishing can beautify both the appearance and the perceived exceptional of the whole structure.

Applications of Fabricated Square Steel Tubing

Structural Frames and Supports

Square steel tubing is typically used to create structural frames for buildings, sheds, warehouses, and bridges. Its capacity to undergo weight whilst resisting bending makes it ideal for columns, horizontal beams, and trusses. Welded frames may be pre-assembled off-site and transported for brief installation, rushing up production timelines.

These fabricated frames offer the skeleton of a constructing and need to be perfectly aligned and welded to maintain structural integrity. Errors in fabrication can lead to lengthy-term stress fractures or alignment issues.

Architectural and Decorative Uses

Beyond structural makes use of, rectangular tubing is likewise discovered in ornamental and architectural packages. It is regularly used in railing systems, staircases, fencing, and public installations where aesthetics rely just as plenty as durability. Welded joints in those packages need to be smooth, seamless, and corrosion-immune to preserve their visual enchantment.

Using square tubing for creative installations or building accents permits for innovative flexibility with out sacrificing electricity. In such instances, TIG welding is typically favored for its capacity to deliver exceptional, easy lines with minimal surface disruption.

Equipment Frames and Machine Guards

In industrial settings, fabricated square tubing is used to construct gadget frames, guards, and safety enclosures. These pieces require both sturdiness and flexibility to healthy the unique format and functions of equipment. Welding square tubing into protective cages facilitates ensure worker protection while maintaining get right of entry to for maintenance or operation.

Proper fabrication in this context consists of precise measurements and steady welds that could resist effect, vibration, and repeated use. Failures in fabrication can cause gadget damage or workplace hazards, so accuracy is crucial.

Conclusion: Building Stronger Structures with the Right Fabrication

Mastering the welding and fabrication of square steel tubing opens the door to a huge range of structural and creative opportunities. Its energy, geometric simplicity, and compatibility with more than one welding methods make it a go-to choice in each commercial and industrial production. With the right preparation, approach, and completing method, fabricators can produce robust, easy, and reliable systems from this versatile material.

For professionals operating with structural steel products, understanding the behavior of square tubing underneath warmness, pressure, and environmental exposure guarantees a higher trendy of safety and overall performance. Whether you’re constructing load-bearing frames or tricky architectural features, the concepts of correct cutting, secure welding, and careful finishing follow to every job.

Frequently Asked Questions

What is the satisfactory welding approach for square metallic tubing?

The fine welding approach relies upon on the utility. MIG welding is green and normally used for preferred fabrication, TIG welding is right for precision and aesthetics, whilst stick welding is suitable for heavy-duty or outdoor paintings.

How do I save you distortion whilst welding rectangular tubing?

To minimize distortion, use clamping fixtures, alternate your welds to stability heat, and keep away from applying an excessive amount of warmness in a single region. Cooling the tubing step by step additionally allows hold its shape.

Can square metal tubing be used exterior?

Yes, but it need to be properly covered or galvanized to prevent corrosion. Using protecting paint or sealants extends its lifespan while uncovered to the factors.

Is rectangular metal tubing higher than spherical tubing for structural use?

Square tubing gives extra flat surfaces and uniform load distribution, making it best for frames and supports. However, round tubing may be higher for fluid systems or dynamic loading, relying at the application.

What equipment are recommended for reducing rectangular metal tubing?

Cold saws, band saws, and chop saws with the perfect blade for steel are most normally used for clean, accurate cuts. Always make certain particular measurements to keep away from becoming issues for the duration of meeting.