Screen Printing: The Best Way to Print on Demand

In the fast-paced world of custom apparel and merchandise, choosing the right printing method can make all the difference. Among the many techniques available today, screen printing has stood the test of time as one of the most reliable, high-quality, and scalable methods for producing vibrant and long-lasting designs. When it comes to printing on demand, screen printing continues to be a top choice for businesses, brands, and designers looking for professional-grade results.

In this article, we’ll explore why modern screen printing near me is considered the best method for on-demand printing, how the process works, what makes it stand out, and when it’s the ideal choice for your business.

What Is Screen Printing?

Screen printing, also known as silk screening, is a traditional printing technique that involves pushing ink through a mesh screen onto a substrate (usually fabric) using a stencil. Each color in the design requires a separate screen, which is aligned carefully to produce the final image.

Though screen printing has been around for decades, modern technology and equipment have made it faster, more precise, and highly adaptable—especially for bulk or repeat orders.

The Screen Printing Process

Here’s a simplified breakdown of how screen printing works:

- Design Preparation: A design is separated by color and converted into individual layers.

- Screen Creation: Each layer of the design is transferred to a mesh screen, coated with a light-sensitive emulsion, and then exposed to light to create a stencil.

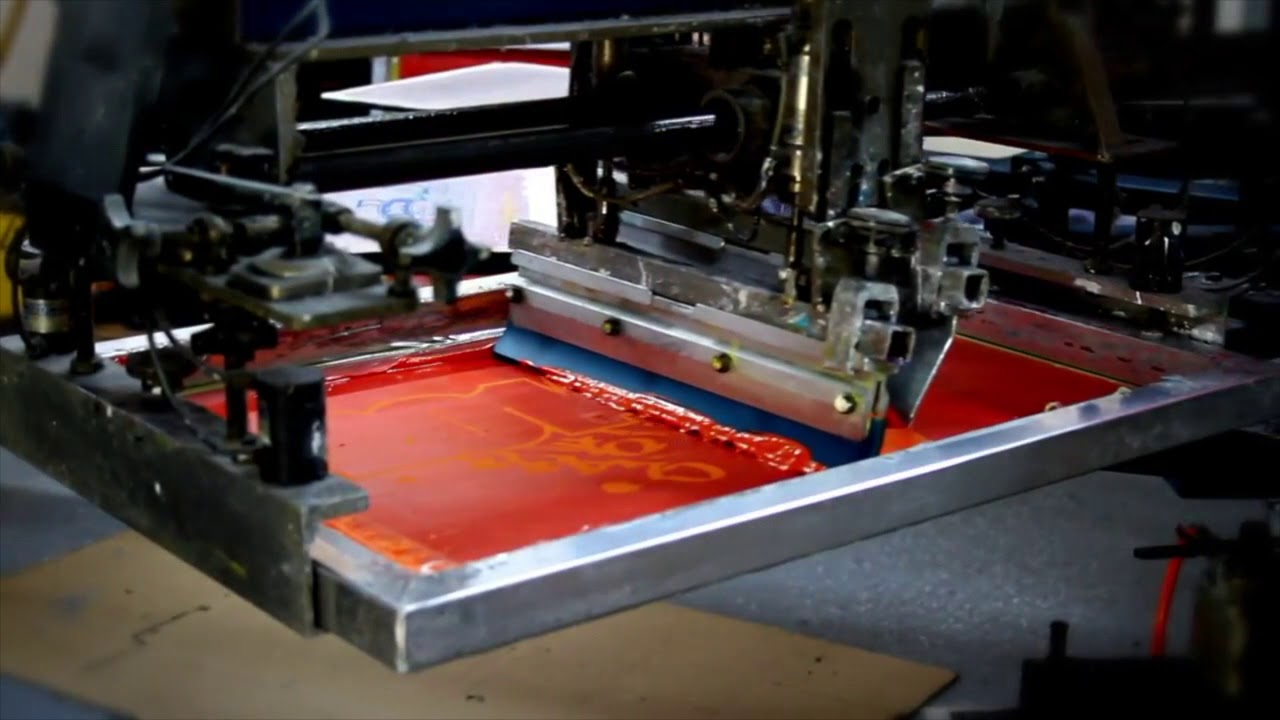

- Ink Application: Ink is pushed through the open areas of the screen using a squeegee, one color at a time.

- Curing: The printed garment is passed through a dryer or heat press to cure the ink and ensure durability.

- Finishing: The final product is inspected, folded, and prepared for shipping or distribution.

Screen printing is particularly known for its crisp lines, bold colors, and high resistance to fading, making it ideal for creating merchandise that lasts.

Why Screen Printing Is the Best for Print on Demand

When we talk about print on demand (POD), we typically refer to fulfilling individual or small-batch orders as they are placed. While digital printing methods like DTG (Direct-to-Garment) are often associated with POD, screen printing can still be the best method for many businesses—especially when balanced with batch production and repeat runs.

Here’s why:

1. Superior Quality

Screen printing produces rich, vibrant colors and solid prints that look professional and feel smooth. Unlike digital methods that may fade or wash out over time, screen-printed designs are incredibly durable and long-lasting, even after repeated washes.

2. Cost-Effective for Volume Orders

One of screen printing’s biggest advantages is its economy of scale. Once screens are set up, producing hundreds or even thousands of garments becomes very cost-effective. If you expect high or repeated demand for a design, screen printing can drastically reduce per-unit cost.

3. Fast Production Times

With automated screen printing machines, large batches can be printed in a short amount of time. For businesses that receive bulk POD orders (e.g., from event organizers, schools, or corporate clients), screen printing ensures quick turnaround and consistent quality.

4. Versatility of Materials

Screen printing isn’t limited to just cotton t-shirts. It can be used on a wide range of products, including:

- Hoodies

- Tote bags

- Jackets

- Hats

- Posters

- Wood and glass items

This makes it an excellent choice for businesses offering a diverse product catalog.

5. Professional Appearance

The opaque and bold finish of screen printing has a premium look and feel. It allows brands to create merchandise that stands out—especially when printing logos, slogans, or brand designs that need to leave a lasting impression.

When to Use Screen Printing in a POD Business

While screen printing excels in many areas, it shines brightest in the following POD scenarios:

- You receive frequent repeat orders of the same design

- You cater to groups, such as schools, sports teams, or events

- Your designs use bold, solid colors rather than intricate photo-quality images

- You want to maintain high brand quality with every print

In these cases, batching orders for screen printing—while still offering the benefits of print-on-demand—can strike the perfect balance between quality and efficiency.

Tips for Successful Screen Printing in POD

- Plan for minimum quantities: Many screen printers have order minimums due to setup costs. Use batching or pre-sales to meet these thresholds.

- Keep designs simple: Limit the number of colors per design to keep costs low and setup easier.

- Work with reliable suppliers: Partner with screen printing providers who understand fast-turnaround, quality control, and e-commerce integration.

- Store frequently used screens: For repeat orders, storing screens reduces setup time and cost.

Final Thoughts

Screen printing remains the gold standard in the custom apparel and merchandise industry. For businesses involved in print-on-demand, it offers a proven way to deliver exceptional quality, build brand trust, and scale profitably—especially when demand increases or when orders can be grouped and processed efficiently.

If you’re looking to make a lasting impression with your custom printed products, screen printing is a smart, strategic choice. With the right setup and workflow, it can be the best method for delivering reliable, on-brand merchandise on demand.