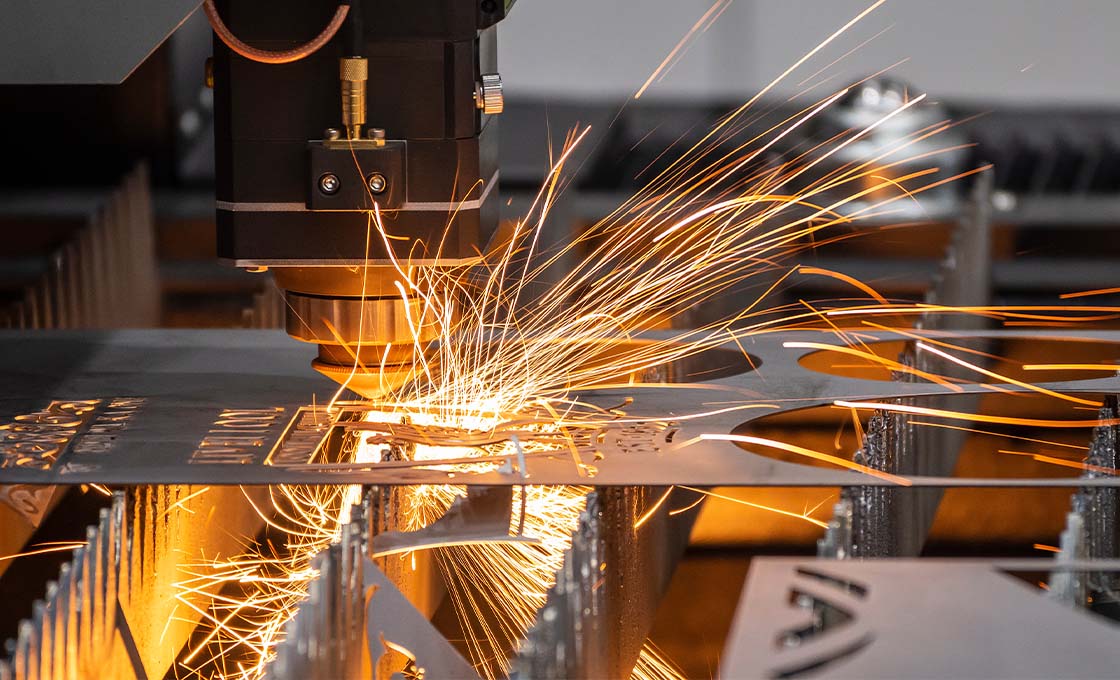

Unlocking Innovation with Metal Rapid Prototyping

In today’s fast-paced manufacturing industry, speed and precision are essential for staying ahead of the competition. Metal rapid prototyping has emerged as a revolutionary process, enabling businesses to create highly accurate, functional prototypes faster than ever before. With its ability to transform digital designs into tangible products, this technique is reshaping how companies bring their ideas to life.

What is Metal Rapid Prototyping?

Metal rapid prototyping is a cutting-edge manufacturing process used to create precise prototypes and functional metal components in record time. Unlike traditional methods that are often time-consuming and costly, this approach uses advanced tools, 3D printing, and rapid prototyping software to streamline product development.

The process allows manufacturers to quickly test designs, refine products, and move seamlessly from concept to production. By using strong, durable metals, prototypes can be tested in real-world conditions, ensuring the final product meets quality and performance expectations.

Why Metal Rapid Prototyping is Changing Manufacturing

The shift toward metal rapid prototyping is driven by the increasing demand for efficiency and customization. Industries such as aerospace, automotive, and healthcare rely on it to reduce production timelines and improve design accuracy.

- Faster Time-to-Market: Products can be designed, tested, and refined in days rather than weeks.

- Cost Reduction: Eliminating multiple rounds of tooling significantly lowers development costs.

- Improved Testing: Functional prototypes made from actual metals provide realistic performance testing.

- Greater Flexibility: Designers can easily make modifications without halting production.

By integrating rapid prototyping software, engineers can visualize and simulate prototypes digitally before physical production, minimizing errors and enhancing efficiency.

The Role of Rapid Prototyping Software

Rapid prototyping software plays a critical role in the success of metal rapid prototyping. It bridges the gap between digital design and physical production by enabling:

- 3D Modeling and Simulation – Create accurate digital prototypes for analysis.

- Error Detection – Identify and correct flaws early in the design phase.

- Seamless Integration – Ensure smooth compatibility with manufacturing systems.

- Time Savings – Automate tasks like slicing and optimizing build paths for faster production.

When combined with metal rapid prototyping, this software becomes a powerful tool for accelerating innovation and reducing design risks.

Applications of Metal Rapid Prototyping Across Industries

The versatility of metal rapid prototyping makes it invaluable across numerous sectors:

1. Aerospace Engineering

Aerospace companies use metal rapid prototyping to produce lightweight, high-strength components for aircraft and spacecraft. Prototypes undergo rigorous testing to ensure they meet safety and performance standards.

2. Automotive Manufacturing

In the automotive industry, manufacturers use metal rapid prototyping to design and test engine components, brackets, and other high-performance parts before mass production.

3. Medical Device Development

Healthcare innovators leverage metal rapid prototyping to create surgical instruments, implants, and custom medical devices tailored to patient needs.

4. Industrial Tooling

Prototyping industrial tools and machinery components using this technology ensures precise performance, durability, and fit before full-scale production.

Benefits of Combining Metal Rapid Prototyping with Advanced Software

When metal rapid prototyping is paired with rapid prototyping software, the results are exceptional. The synergy between physical prototyping and digital design tools leads to:

- Enhanced Accuracy: Complex geometries can be designed and produced flawlessly.

- Reduced Waste: Optimized designs minimize material use.

- Faster Iterations: Rapidly test and refine prototypes without delay.

- Improved Collaboration: Teams can share digital prototypes globally, streamlining workflows.

These advantages make it easier for companies to innovate faster, reduce costs, and maintain a competitive edge.

How Zintilon Delivers Excellence in Metal Rapid Prototyping

At Zintilon, our focus is on delivering high-quality metal rapid prototyping solutions tailored to diverse industries. By leveraging advanced machinery, expert technicians, and state-of-the-art rapid prototyping software, we ensure every project meets the highest standards.

Our approach is built on:

- Precision Engineering – Every prototype undergoes meticulous quality control.

- Fast Turnaround – From concept to prototype, we minimize lead times.

- Material Versatility – We offer various metals suited for functional and durable prototypes.

- Collaborative Support – Our team works closely with clients to optimize designs and ensure success.

Future Trends in Metal Rapid Prototyping

As technology continues to evolve, metal rapid prototyping will become even more advanced. Emerging trends include:

- AI-Powered Design: Integrating artificial intelligence into rapid prototyping software for automated optimization.

- Sustainable Manufacturing: Using recycled metals and reducing energy consumption during production.

- Hybrid Manufacturing: Combining additive and subtractive processes for greater flexibility and efficiency.

These innovations will further solidify metal rapid prototyping as a cornerstone of modern manufacturing.

Conclusion

Metal rapid prototyping is revolutionizing how industries design, test, and manufacture products. By merging the speed and precision of this technology with powerful rapid prototyping software, businesses can bring innovative ideas to life faster and more efficiently than ever before.

Whether in aerospace, automotive, healthcare, or industrial manufacturing, metal rapid prototyping is the key to staying competitive and driving progress in an ever-evolving market. For businesses seeking excellence in prototype development, adopting this technology is no longer optional—it’s essential.